If you are building a senior 20 organ, or considering building one, then at some point in time you will require a music spool in order to complete the pressure box assembly. You will need it to align your music with the tracker bar and you will need it to complete the final mounting parts for the spool and the rewind mechanism. The senior 20 organ was designed by John Smith to use commonly available items. I am not sure how common the spool is, however, here in the US it is a hard to find item. The cost of the spool is pretty high as well so I attempted to make some myself. Its hard to find the exact dimensions of the spool, however this is what I came up with. The spool ends have a diameter between 70 and 75 mm and the distance between the ends needs to be be no more than 141mm so you will need to use trial and error to get these spools perfect.

The spool ends are made from plastic. I tried both delrin and nylon and both are strong enough and easy to work with. I purchased pieces that are 7/64 of an inch in thickness from McMaster Carr. The smallest piece of delrin you can order is 12” by 12” and the smallest piece of nylon is 6” by 6”. Since the spool end is less than 3 inches in diameter, you can make 2 spools from a single piece of 6×6 nylon.

Mcmaster Carr http://www.mcmaster.com

Delrin https://www.mcmaster.com/#acetal-homopolymer-sheets/=14w87mt 12×12 black 8575K285

Nylon https://www.mcmaster.com/#standard-nylon-sheets/=14w89nx 6×6 white 8539K887

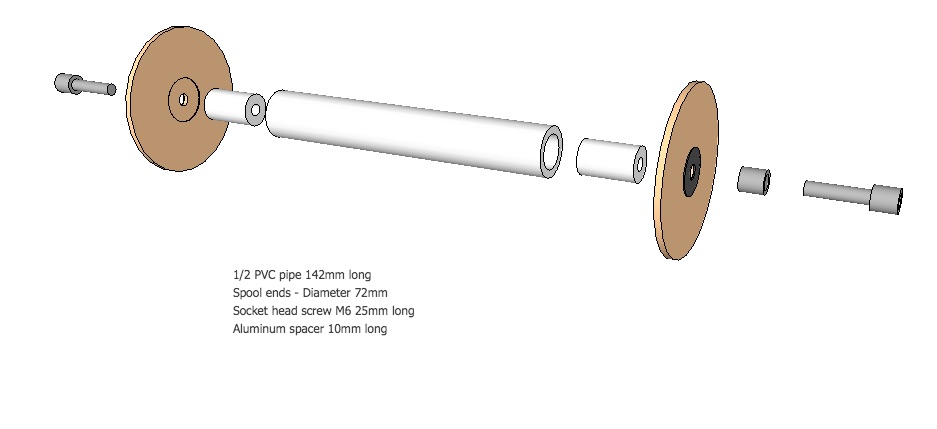

I used standard 1/2” PVC pipe for the spool pipe and filled it with a wooden dowel than was turned to the inside diameter of the pipe. 1/2” PVC pipe has an internal diameter of around 15.5 mm and an external diameter of 21.5mm. I drilled a 1/2 mm recess in the spool ends to align the pipe with the ends and joined the ends to the pipe with standard 6 mm socket head screw3s. You will need to extend the rewind side out by 10mm and I used an aluminum spaced for that. 6mm socket head screws accept a 5mm hex wrench and have a 10mm diameter head which retains compatibility with the original spool.

I also used a tip that I found on the Merlwyn Wright website to have a sloped entry for my music spool. This keeps the spool firmly down as music is being wound or unwound from the spool.

Overall these spools are easy to make and especially useful for the test roll than comes with the plans. I have a sketchup model here which provides the dimensions of the spool I made.